This article will talk about the most important aspects of installing access flooring. It is not always simple to anticipate what it is that you will need from your access flooring. Not only is it difficult to anticipate what you can anticipate from the installation once it is finished, but it is also difficult to anticipate what your needs will be prior to the installation. Because of this, the team at Accessfloorstore. com has singled out a handful of essential elements that are necessary for a successful access flooring installation.

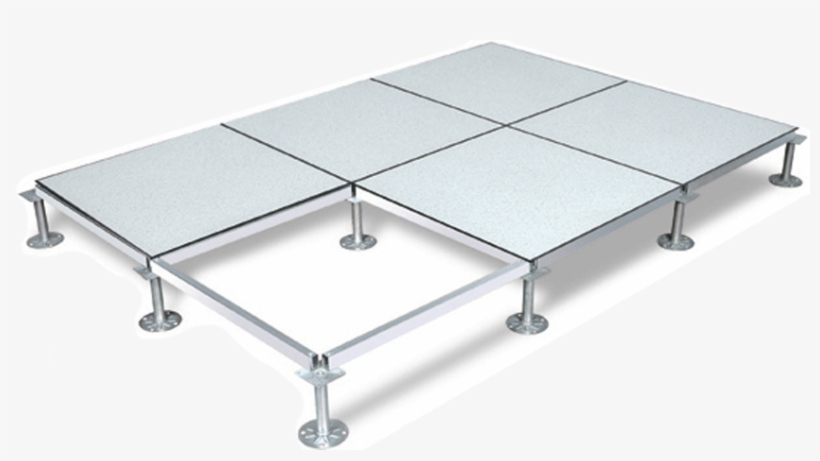

The following is a brief discussion of the three primary components, which are referred to as floor panels, a pedestal, and a stringer:

- Floor panels: These panels are definitely an essential part of any access flooring project, as they are used to create the final flooring within the room.

- Because of this, these panels are an important component of any access flooring project.

- Raised floor systems are possible to remove floor panels in order to gain access to whatever is located underneath them, which is one of the reasons why access flooring is such a popular choice in the professional fields.

- This is one of the reasons why access flooring is so beneficial

The pedestal will serve as the supporting structure for the raised flooring panels. It will be positioned on top of the subfloor and then secured in place there. In most cases, an adhesive made of epoxy resin is used for this procedure. The head for the panel location can be attached to the pedestal, which also allows the pedestal to be adjusted to the required height of the flooring.

Stringer: The pedestals’ ability to perform their intended functions correctly is dependent on the presence of the stringer. It does so by affixing itself to the pedestal head in order to provide additional support for the flooring. In essence, it contributes to the creation of better structural performance for the system that supports the raised floor.

In addition to having an understanding of the various components that go into the creation of an access flooring installation, it is extremely important to be familiar with the function of the flooring. One of the most common justifications for selecting access flooring is the fact that it offers some level of protection.

Pipes and wiring are just two of the many components that must be assembled before a structure can be considered complete. It is necessary to properly secure these items and conceal them from view in order to ensure that they are safeguarded. The installation of access flooring is necessary at this point. You can safeguard all of these items by utilizing a floor that provides access, and at the same time, you can still get to them quickly and easily if you need to. The Raised Floor is typically used for the following purposes, as shown in the examples of completed projects that follow:

- General office space (New Sasol HQ, New Discovery HQ, New Old Mutual HQ in Sandton);

- Auditorium Floors (New Outsurance HQ);

- Call Centres (New FNB Contact Centre Randburg, Eskom);

- Data Centres (Existing Absa Randburg)

- Casinos – All In addition, to address:

- Cabling for telecommunications systems

- the detection and suppression of fires

- the reticulation of water and drainage

- the provision of electrical power (Eskom)

Access flooring, in addition to safeguarding these components in your office environment, can also be used to create different levels of flooring. The same principles that were discussed earlier still apply, but now the pedestals are used to create varying heights, making them the ideal solution for a business that requires a seminar room, for instance. The Raised Floor enables the creation of the various levels required for seating while simultaneously ensuring the integrity of all components, such as the cabling.

Accessfloorstore.com is widely regarded as one of the most reputable providers of access flooring in South Africa. The company has been successful in the access flooring market for a very long time, and it offers its solutions in a variety of different finishes. The solutions provided by Accessfloorstore. com have a high breaking strength, are cement filled, and have steel corners that have been specifically designed to ensure their durability. Their panels have been put through extensive performance testing, and they offer some of the panel designs that are currently enjoying the greatest level of adoption across the globe.

Strong apexes in all four corners

The panels sold by Accessfloorstore. com all come equipped as standard with drawn steel beam corners that are 90 degrees and filled with high strength cement. Any load that is placed on the panel will first be transferred to the panel corners, and then it will travel through the pedestals and down to the sub floor. In order to achieve the ultimate load capacity that is required, their deep drawn beam corner is manufactured using a complicated process. This is done despite the fact that it is difficult. This prevents the corners or panels from dishing upward or bending upward in any way. In order to ensure that the panel is completely saturated with cement, an injection pump operates at a high pressure. The ultimate determining factor in the quality of a raised floor system is the strength of the corner areas of the panel.

Carrying capacity

The point at which a panel gives way under its maximum load is the definition of its ultimate load capacity. The panels sold by Accessfloorstore. com are designed and constructed with a minimum safety factor that is 2.5 times the design load. This prevents the failure that could otherwise lead to injuries or significant damage to the equipment.

The cost of a failure would far outweigh the initial savings on a cheap system, so the point of failure or collapse is the single most important indicator of performance. The point of failure or collapse is also known as the point of collapse. When choosing an raised floor system panel for your application, you need to make sure that you take both the ultimate distributed load and the concentrated load value into consideration. Outside of the SABS, the testing laboratory that Accessfloorstore. com possesses is the only one in South Africa that is accredited.